The “green” alternative to traditional plastics is part of a complex world that still presents a number of critical issues.

The definition

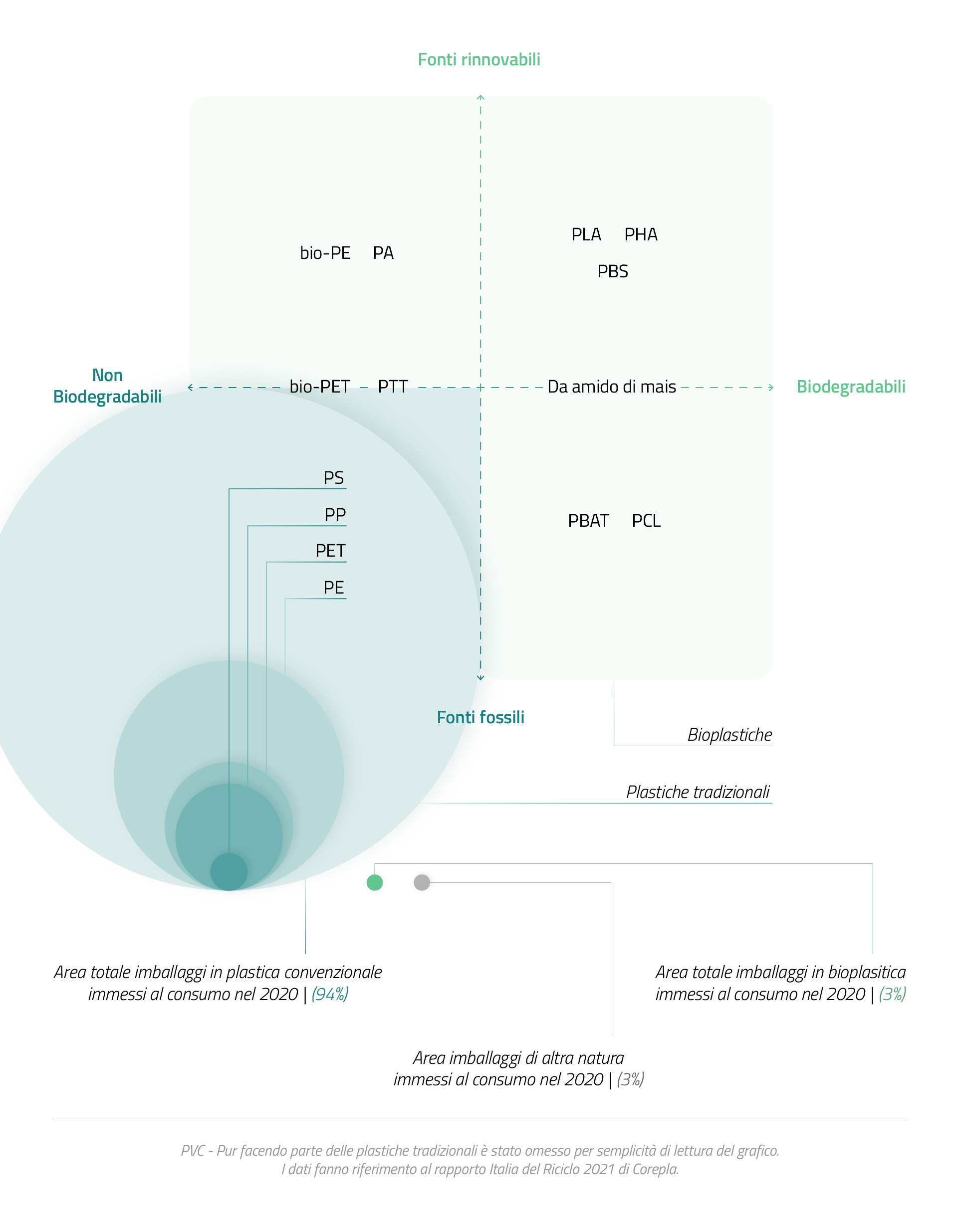

Bioplastics are materials with properties similar to “traditional” plastics but different in terms of: derivation from renewable raw materials; biodegradability; compostability. The definition does not necessarily imply that these three characteristics are always present and guaranteed at the same time, but it is sufficient that at least one of these conditions is met.

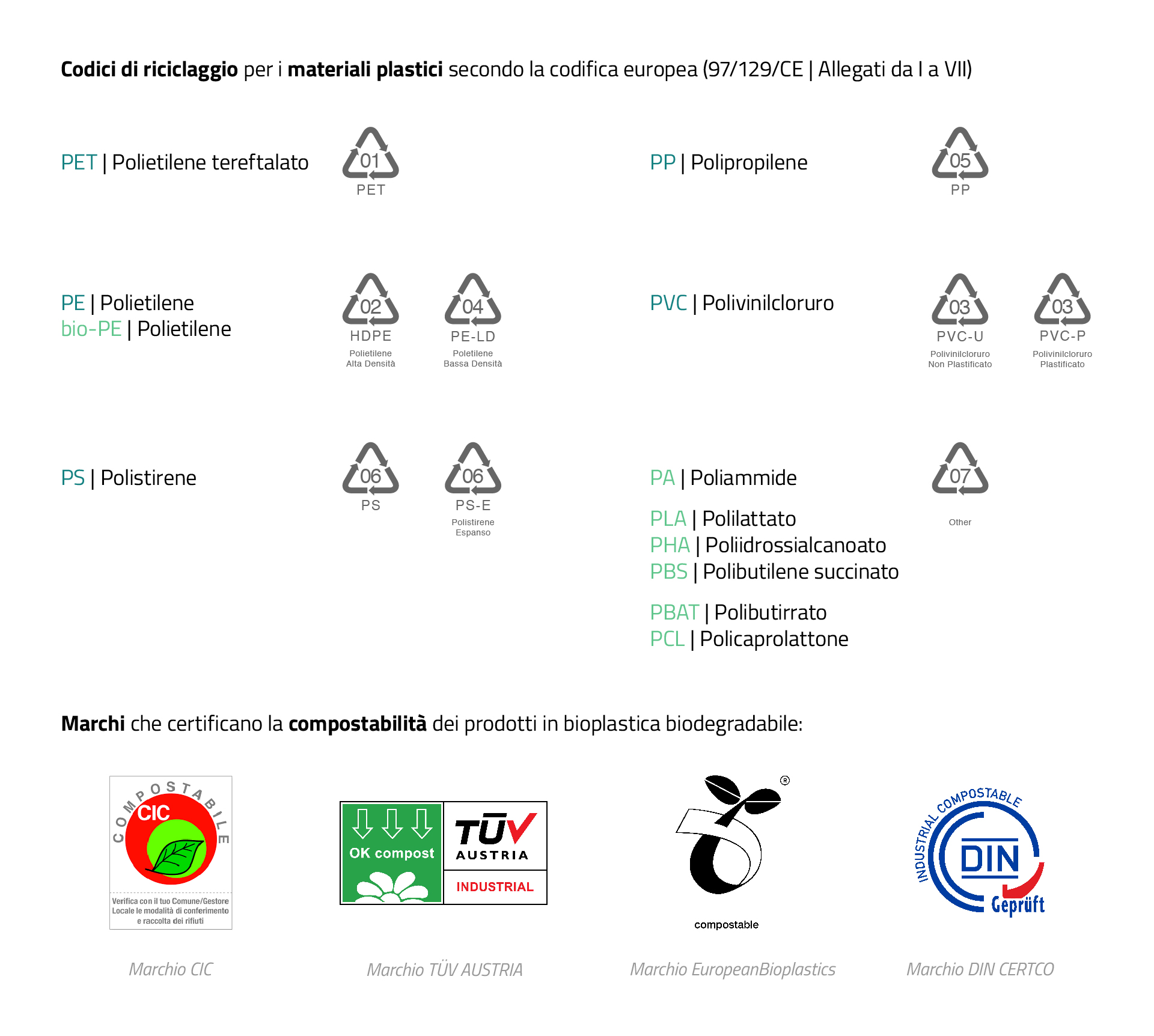

This implies the existence of bioplastics that are derived from fossil sources (totally or partially) and are biodegradable, or that are derived from renewable sources but are not biodegradable (such as bio-PET). Furthermore, some biodegradable bioplastics may be compostable, but only if they possess specific characteristics. To be compostable, such materials must pass the biodegradability test (degrade by at least 90% in 6 months in a carbon dioxide-rich environment) and the disintegration test (after 12 weeks in contact with organic materials, the material must consist of 90% of fragments smaller than 2 mm).

After all, useful to know that there is another degradability category (banned by the Single-Use Plastics Directive) called oxo-degradable. These are plastics that, thanks to the addition of additives, are able to degrade in a short time into small parts.

A sustainable solution?

Despite the fact that the production of bioplastics is increasing and that they can be useful in certain cases, these materials still present critical issues, particularly when used for packaging and disposable products.

First of all, a problem that still persists is related to the improper disposal of bioplastic products, particularly in the waste management of plastic. In fact, bioplastic packaging and rigid containers cannot be distinguished at first sight from plastic ones. This often leads to the first one being confused with the second one and thrown into the plastic bin, thus causing problems in the treatment plants, where it is difficult to distinguish between the different materials with current technology. Good practice is to check the type of material before throwing a waste away.

In a recent survey by Greenpeace further critical issues are highlighted, in the case of compostable bioplastics being placed in the organic fraction. In fact, Greenpeace states that Italy is one of the few countries to differentiate rigid compostable plastic with organic waste. However, 63% (source: ISPRA data) of this fraction ends up in anaerobic digestion plants or integrated plants (composting and anaerobic digestion), which are hardly able to degrade rigid bioplastics. The remaining 37% is instead treated in composting plants, which are efficient at degrading these materials; however, there is no guarantee that rigid bioplastics remain in these plants long enough to ensure their complete degradation. Furthermore, in some plants, seaving takes place to separate rigid materials from the organic fraction: this also separates rigid bioplastics, which, together with the waste, will be sent for energy recovery or disposed of in rubbish dump.

|

|

Assobioplastiche replies that organic waste treatment plants in Italy are qualified and efficient in the management of compostable plastic packaging and that plants that do not treat compostable bioplastics represent “a few exceptions, due to particular pre-treatment systems”. It also disputes the percentages published by Greenpeace concerning the delivery of the organic fraction to treatment plants: Assobioplastiche states that 5,1% ends up in anaerobic plants and 46,8% in integrated plants, which have the composting phase after the anaerobic one.

Greenpeace gave a further answer claiming that Utilitalia and the European Compost Network confirm the inadequacy of anaerobic plants in treating these products and that, according to ISPRA data concerning only the organic fraction containing bioplastic materials, 63% is confirmed to be delivered to plants that process rigid bioplastic products.

Finally, it is crucial to consider biodegradation in the natural environment, in the event of accidental and non-accidental dispersion. The National Reserch Center (CNR,) together with the National Institute of Geophysics and Volcanology and the Ligurian District for Marine Technology, has published the first data of a study on this subject, which is still in progress. According to this preliminary data, the study states that, if dispersed in the environment, bioplastics have very long degradation times, comparable to those of 'traditional' plastics. In particular, the experiment examined two bioplastic polymers and two of the most widely used in plastic packaging whose samples were placed in a marine environment (inside cages) and on the beach (in a tank exposed to the environmental elements).

Assobioplastiche responds through its technical committee pointing out a number of critical aspects of the experiment. First of all, it states that the structure of the cages would create an environment not optimal for the degradation, then it underlines the lack of clarity on which portions of the sample were analysed, also contesting the observation with the electron microscope which, being limited to the surface of the samples, would not be able to really define the degree of degradation. In the end he criticises the timing of the analysis, linking it to a misunderstanding of international standards (which would certify a material as biodegradable and compostable in six months but only if in a controlled environment).

For more information:

Anche le bioplastiche si degradano lentamente nell'ambiente (CNR)

La gestione e il recupero delle bioplastiche (Utilitalia)

Read also: